What Makes Himalaya Variable Geometry Plate Rolling Machines So Special?

- Rohan Shah

- Oct 26, 2023

- 6 min read

Updated: Jan 5, 2024

Purchasing a plate rolling machine isn’t a decision you come across every day. It’s a huge investment that will have implications for decades.

However, the decision gets difficult with so many manufacturers offering machines of different varieties and prices. And when you add variable geometry plate rolling machines into the mix, the choice gets even more baffling.

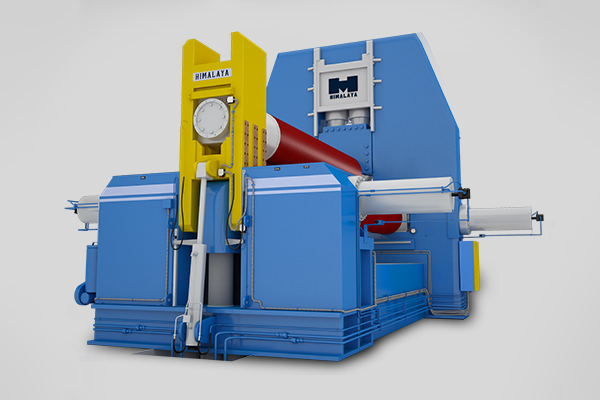

We at Himalaya Machinery have been manufacturing plate bending/rolling machines for 40+ years, and one of our most popular machine types is the variable geometry plate bending/rolling machine.

These machines have earned the trust of reputed companies like Godrej & Boyce and Bharat Tanks And Vessels LLP. Let us help you understand what makes them a great choice for your fabrication needs.

What is a Variable Geometry Plate Rolling/Bending Machine?

A Variable Geometry Plate Rolling Machine is a three-roll plate bending machine with an extra feature. The key feature that makes this machine different is the ability of its rolls to move independently and the ability to make complex metal structures at a faster speed.

Making them the perfect choice for demanding medium-to-heavy-duty rolling applications, such as shipbuilding and making rocket shells. Variable geometry machines offer exceptional performance that rivals even the most costly 4-roll plate bending rolls.

These machines bring many benefits to your fabrication setups. They increase production capacity while reducing upfront costs and keeping ongoing expenses in check. They are an attractive investment for heavy thick plate applications (above 80mm).

Let's understand its design to determine what type of impact this equipment might make on your shop floor.

The Design of Himalaya’s Variable Geometry Plate Rolling Machines

A Variable Geometry Plate Rolling/Bending Machine provides the same precision and accuracy level as other plate rolling machines. But these machines help you build more intricate metal structures.

Look at Images 1,2,3 and 4. The images represent a stage-wise plate-rolling/bending process for Himalaya’s variable plate bending machine. Let’s run down how this machine works.

Image 1 Image 2

Image 3 Image 4

Stage-Wise Rolling/ Plate Bending Process

Types Of Rollers

These machines come with three rollers: the left bottom roll, the top roll, and the right bottom roll. A plate roller to shape the material into a cylinder requires something to grip. As a result, any operation of a plate rolling machine leaves an unbent flat end section.

Here, the flat end is minimized. How? (See Image 2) The plate is fed into the machine from the left side. The top roll acts as a press ram, while the left bottom roll acts as a lower press die. The right bottom roll supports the plate as it is fed into the machine.

The top roll applies direct pressure to shape the leading edge into the desired radius. The left bottom roll axis displacement helps achieve this. The subsequent rotation continues to deliver the desired curve. (See Images 3 and 4)

The Special Configuration

These machines have the ability to adjust the position and shape of the bending rolls. This feature enables the machine to handle a wide range of metal shapes from simple arcs to intricate designs.

Do you know that these machines have high rolling capacity? Due to the flexible bending span of the bottom rolls, the rolling capacity can be 15% to 20% higher compared to machines with the same top roll diameter that use linear guideways or swing-guide designs.

Independent Movement

The hydraulic cylinders help the plate bending rollers move independently. The top roll moves vertically, and the bottom roll moves horizontally. Integrated planetary gearboxes with hydro-motors make this rotation possible.

Resulting in optimal central distance between the bottom rolls and the distance between the bending points. Isn't this a great advantage?

Thin and Thick Plates

Variable geometry plate bending machine roll span can be drastically reduced for thin plates. Generating traction, avoiding driving slippage and spring-back. Thick plates can have an increased bending span, reducing the plate load and minimizing deformation.

To achieve better edge-bending quality, you can adjust the bottom rolls, moving them independently and positioning them asymmetrically. Additionally, you can utilize a basic unpowered conveyor to load the plates, which can be a cost-saving measure.

Now that you are familiar with the design let’s see how it can benefit you in your workspace.

Perks Of Variable Geometry Plate Rolling Machines

What does your workshop need when fabricating metals? Efficiency, higher degree of accuracy and precision, reduced time and effort? So, you want to enhance your manufacturing capabilities, right? Don't worry! You are at the right place.

Here are the five benefits of Himalaya's Variable Plate Rolling Machine.

1. In-built Cone Bending Operations

Our machines provide an excellent and important feature at no extra cost - it's the in-build cone bending operation.

The process is simple: Plate feeding becomes convenient as the bottom roll moves horizontally. You only need to incline the top roll to achieve cone-bending geometry. The electronic microprocessor on some of our models controls and monitors this process.

How is this helpful for your workshop? This pre-pinching process allows you to connect both ends of the rolled plate with precision. First, it will save your resources for other fabrication work. Second, be rest assured about the efficiency and effectiveness of the rolled metal plates.

2. Service Support

As our motto says, 'Caring for the old, rearing for the new,' we offer a range of services tailor-made for you. We provide remote service advisory, service, and repairs for machines, spare accessories, and so much more. Isn't this a great relief?

How is this helpful for your workshop? You can nudge us with unexpected repairs and replacements. The repairs will be timely, and you will not have the financial burden of making those repairs each year.

3. Excellent Build Quality

Himalaya machines have a sturdy steel structure made from heavy metal plates. Our rolls have optimal diameter and we use forged carbon steel rolls machines by high precision CNC lathes.

Moreover, you can custom order crown-machine rolls according to your requirements. We crown our rolls to compensate for roll deflection during the bending process.

Our state-of-the-art machines boast a highly efficient Himalayan Planetary driving system. This eliminates energy waste and maximizes productivity. Yet, they achieve the goal of speed reduction by increasing the stages in gears and pinions.

How is this helpful for your workshop? The first ever machine we sold 40 years ago is still up and running. So put your faith in our variable geometry plate rolling/bending machines to ensure smoother operations, higher productivity, and durability.

4. Complementary Cooling System

Rest assured with our machine's complementary cooling system, as it ensures an extremely longer life of the hydraulic system. Moreover, a tropicalized oil cooling system assures nonstop operations in hot working conditions.

How is this helpful for your workshop? You can manage heat during the rolling process. This feature will offer temperature control at hot climatic locations, such as India. Your productivity will also increase and the machines will provide safety at the job site.

5. Availability of Models

Himalaya offers machines according to your application and requirements. Our machines have fixed as well as variable speeds. Here is the V-series product range.

Model | Top Roll Size | Bottom Roll Size | Rolling | Pre-Pinching |

VMH/30 | 535 | 465 | 72 | 46 |

VAH/30 | 730 | 600 | 125 | 80 |

VSH/30 | 830 | 710 | 150 | 100 |

*All capacities are as per 26 Kg/mm2 (Yield Strength of Plate Material)

* All dimensions are in mm.

How is this helpful for your workshop? You get the option to choose from the most suitable equipment for your specific projects and preferences.

As a workshop owner, you would think that such a machine might not exist. But it does and we offer them. Apart from our exceptional build quality and design, we offer additional features.

What Are the Additional Features That Himalaya Offers?

Your workshop has the opportunity to greatly enhance productivity with the following additional features offered by Himalaya. Let’s have a look!

Surfaced-Hardened Rolls: For additional durability and longevity. The surface hardness ranges between 42 to 55 HRC.

Interchangeable Top Rolls: Add versatility for large-size machines for rolling small-diameter shells. For instance: An interchangeable top roll of 350 mm diameter with a 470 mm top roll diameter.

Hard Chrome Plates Rolls: For special applications in the Pharma and Dairy Industry.

Central & Side Shell Supports: For ease of operational cost, productivity, and increased safety of workers.

Tilting Table: For providing specific angles to support the feeding plates.

Powered Conveyors: To feed larger plate lengths, improving machine performance and longevity.

PLC Control: Used to provide precision, ease of operation, prevent maintenance, and increase machine life.

Final Words

We are confident that our variable geometry plate rolling/ bending machine has left a lasting impression on you. Our valuable clientele, which includes Bharat Tanks and Vessels, Phils Heavy Engineering Pvt Ltd, and more, can attest to the unmatched quality of our products.

So, feel free to contact us for any metal fabrication machinery needs. We offer so much more.

Comments