Plate Bending Machines Vs. Section Benders: Which to Use?

- Rohan Shah

- May 21, 2025

- 6 min read

The right type of bending machine is critical to smooth heavy manufacturing operations.

And, if you go for a machine that isn’t the correct fit for your manufacturing category, then you could face several problems like:

Inaccurate bends

Wasted raw material

Missed deadlines

Expensive rework

Structural integrity of the final product

When selecting the type of bending machine, you have two great options: plate-bending machines and section benders.

But, making the correct choice between both can be difficult if you don’t know how they differ from each other!

It’s because both do a similar job, but they do it for different kinds of metals and in different ways.

In this blog, we will discuss the characteristics of both the bending machines, their key differences and when to use them so you can choose the best option for your production process.

Plate Bending Machines vs. Section Benders: Table of Contents

What Are Plate Bending Machines?

What Are Section Benders?

The Key Differences Between Plate-Bending Machines And Section Benders

When To Use Plate Bending Machines?

When To Use Section Benders?

Get The Best Metal Bending Machine From Himalaya Machinery

Plate bending machines vs. section benders: FAQs

What Are Plate Bending Machines?

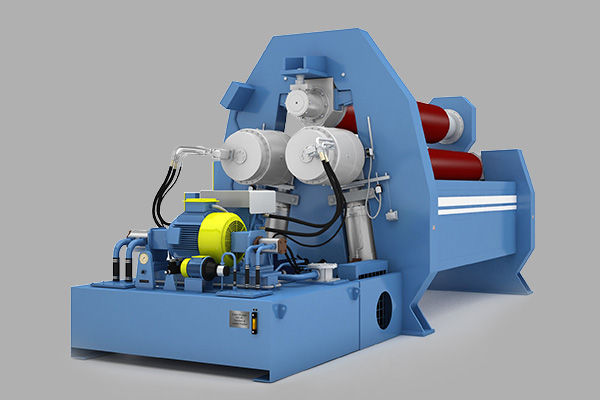

Plate Bending Machines are popularly known as “Plate rolling machines” or “Roll bending machines” in the industrial arena.

This machine consists of rollers that bend the flat metal sheets to give them a conical or cylindrical shape.

A plate-bending machine is normally available in two versions:

3-Roll Machine

This version consists of three rollers placed in a triangular form.

One roller is placed at the top, which moves vertically and two rollers below on both sides, which move horizontally.

The machine uses the top roller to press the metal plate between the other two rollers.

It can bend metals of various thickness levels and cylinders of different diameters.

4-Roll Machine

You’ll find four rollers in this machine that are set in a rectangular formation.

Two small rollers remain at the top, and the other two rollers, the larger ones, are placed at the bottom.

The large rollers push the metal plate, and the roller on top applies pressure to bend it.

This version offers more precision and reduces the chances of deformation.

These two plate-bending machines are used in pressure vessel manufacturing, shipbuilding, aerospace, steel, infrastructure, and papermaking industries.

What Are Section Benders?

Section benders work differently from roll bending machines.

These machines bend metals with a structural shape, instead of flat metal plates.

The complex structural shapes that these machines are capable of bending are:

Angles

Tubes

I-beams

Channels

Pipes

T-sections

A section bender also has three rollers placed in a triangular form that apply pressure on the metal structure and bend it according to your required shape.

Don’t confuse it with the 3-roll plate bending machine, as that particular machine is made to work only on flat metal sheets.

These machines are generally of three categories.

Horizontal Section Bending Machines

This type of machine bends metal structures on a horizontal axis and is best for heavy-duty usage. It is mostly used in the construction and shipbuilding industries.

Vertical Section Bending Machines

In this category, the rollers move vertically to shape the metal. They are perfect for places where space is limited and tight-radius bends are needed. For example, you can use this machine in compact production areas like a small metal workshop.

Universal Section Bending Machines

This is the best machine if you need more complex angles and shapes. It can work on metals of several shapes and sections, and may also have more than two rollers. Most big automotive, aerospace, and engineering companies use this type of bending machine.

Section bender machines play a critical role in industries that require complex metal structures and curves. Such industries include steel manufacturing, infrastructure projects, vehicle manufacturing, aerospace and more.

Pro Tip: We have seen that passing the metal through the roller multiple times or adjusting the roller’s settings can give you more control and precision over the metal forming process.

What Are The Key Differences Between Plate-Bending Machines And Section Benders?

So, as you saw, both these machines do the broader job well: metal-bending.

But a plate-bending machine and a section bender differ in certain aspects. We will discuss these differences based on these parameters.

Plate Bending Machines

The defining features that set Plate Bending machines apart from Section Benders:

Material Type: Handles flat metal plates such as mild steel, stainless steel, or aluminum.

Output Shape: They bend or reshape these metal plates into cylindrical, conical, or high-radius shapes.

Precision Level: It handles large-diameter components more precisely than smaller ones.

Machine Size: The plate bending machines generally come in a large size compared to section benders.

Industries: Pressure vessel manufacturing, shipbuilding, aerospace, steel, infrastructure, papermaking and more.

Section Benders

The properties that make section benders a go-to choice for heavy engineering industries:

Material Type: It handles metal of different structural profiles, such as pipes, beams, angles, channels, and T-sections.

Output Shape: They produce metal shapes like spirals, arcs and rings.

Precision Level: You can control the bending process, so, you can achieve a high level of accuracy and precision.

Machine Size: While also big in size, section benders are comparatively smaller than plate-bending machines.

Typical Industries: Steel manufacturing, infrastructure projects, vehicle manufacturing, aerospace and more.

Now that we’ve gone through the key differences between section benders and plate benders, the question is: which bending machine is right for you?

That’s exactly what we’ll explore in the next section:

When To Use Plate Bending Machines?

First, let me walk you through situations where a plate-bending machine should be your go-to solution:

If you have flat metal sheets that need to be shaped like a cone, cylindrical or something with a large radius curve.

When you need to roll medium or thick metal sheets up to 150mm or more with a consistent thickness.

At times when dealing in high-volume industrial fabrication, for example, pipes, pressure vessels, wind turbine towers, and heavy equipment shells.

At a modern manufacturing site, you may need CNC controls, hydraulic synchronization, and automated feeding systems.

When To Use Section Benders?

Next, let’s look at the kind of scenarios where a section bender makes more sense for your bending requirements:

If you are working on a project that requires metal structures such as beams, tubes, angles, channels, or T-sections.

When your target is to bend the metal structure into tight radii, rings, or complex curves.

In situations where you just need to change the pre-formed sections, without messing up their cross-sectional integrity.

When you need to handle asymmetric or irregular metal profiles.

If you're working with lighter materials, intricate part designs, and when you need control over the process, plus precision and efficiency.

Get The Right Metal Bending Machine From Himalaya Machinery

Simply put, you should use a plate-bending machine if you handle flat metals in your daily operations and need a large-radius or conical rolling machine.

Similarly, if you are dealing with tubes, beams, or channels that must be given precise curves, you can simply use a section bender machine.

No matter which one you buy, you should get it from a trusted section-bending and plate-bending machine manufacturer.

At Himalaya Machinery, we engineer custom hydraulic plate-bending machines and section benders that are built for durability, precision, and CNC automation.

We have been building these machines for the last four decades, and this experience shows in every successful project we’ve overseen, from how they perform to how long they last.

Plus, our skilled engineers will provide end-to-end support for our products and your existing machinery.

Reach out to us today and learn more about our range of products.

Plate bending machines vs. section benders: FAQs

1. What is the difference between a plate-bending machine and a section-bending machine?

The core difference between a plate-bending machine and a section-bending machine is that:

A plate-bending machine can work with flat metal sheets, giving them shapes like a cone or high-radius curve with high precision.

A section-bending machine can give shapes like arcs, rings, or tight curves to metal structures like beams, tubes, and angles.

2. Can section benders bend flat plates or sheet metal?

No, a section bender is not built for bending flat plates or sheet metal. If you need to bend flat plates or sheet metal, we recommend using a plate-bending machine. The job of a section bender is to bend metal structures like angles, pipes, or channels.

3. How do I choose the right bending machine for my application?

You can choose between the machines depending on the type of material you are handling and the type of shape you want from it.

If you want to convert a flat sheet into a large curved structure, then choose a plate-bending machine.

You can also choose a section bending machine to bend beams, tubes, or shapes with complex angles.

4. Which industries use plate bending and section bending machines?

Industries that use plate benders: Shipbuilding, steel manufacturing and pressure vessel manufacturing.

Industries that use section benders: Construction, architecture, heavy engineering, railways, and automobile manufacturing.

Comments